How Is Embroidery Fabric Different from Printed Fabric?

Share

Textile manufacturing encompasses numerous decorative techniques, with embroidery and printing representing two fundamentally distinct approaches to fabric enhancement. Historical documentation traces embroidery traditions back approximately 30,000 years, while textile printing emerged during the 3rd century in China before spreading globally. Contemporary textile science distinguishes these methods through structural analysis, production methodologies, and performance characteristics. Understanding these differences becomes crucial for designers, manufacturers, and consumers selecting appropriate materials for specific applications, particularly when considering durability requirements, aesthetic preferences, and cost parameters.

What Is Embroidery Fabric?

Embroidery fabric material refers to base textiles specifically engineered to accommodate needle penetration and thread manipulation during decorative stitching processes. Technical specifications for embroidery-suitable fabrics include:

Structural characteristics:

- Weave density between 80-120 threads per inch provides optimal needle passage

- Fiber composition typically features cotton, linen, or cotton-polyester blends offering dimensional stability

- Thread count ranges from 200-400 for fine embroidery work, with higher counts supporting intricate detail

- Surface texture remains relatively smooth to prevent thread snagging during machine or hand stitching

Performance specifications:

- Tensile strength ratings exceed 15 pounds per square inch to withstand embroidery tension

- Fabric weight ranges from 4-12 ounces per square yard, depending on intended application

- Shrinkage rates below 3% after washing ensure design integrity maintenance

- Colorfast ratings of 4-5 on standard testing scales prevent dye bleeding during embroidery processes

Research from the Textile Research Institute indicates that embroidery work fabric undergoes physical modification during stitching, with thread penetration creating permanent structural changes that enhance fabric stability while potentially reducing flexibility in heavily stitched areas.

What Is Printed Fabric?

Printed fabric encompasses textiles decorated through various ink or dye application methods applied to fabric surfaces without structural modification. Contemporary printing technologies include:

Digital printing processes:

- Inkjet systems deposit water-based or pigment inks directly onto fabric surfaces

- Resolution capabilities reach 1440 dots per inch for photographic quality reproduction

- Color gamut spans 95% of visible spectrum through advanced ink formulations

- Production speeds range from 100-300 square meters per hour depending on complexity

Traditional printing methodologies:

- Screen printing employs mesh stencils for ink application, achieving opacity levels up to 100%

- Rotary printing utilizes engraved cylinders for continuous pattern application

- Block printing involves hand-carved stamps for artisanal fabric decoration

- Heat transfer processes apply pre-printed designs through thermal activation

Technical analysis reveals printed fabrics maintain original structural properties while adding surface design layers typically measuring 0.1-0.3 millimeters in thickness. Laboratory testing confirms that quality printing processes exhibit wash fastness ratings of 4-5 and light fastness ratings of 6-8 on international testing standards.

Key Differences Between Embroidered and Printed Fabrics

Manufacturing process distinctions:

Embroidery designs fabric creation involves mechanical needle manipulation creating raised surface textures through thread layering. Stitch density calculations range from 5,000-15,000 stitches per square inch for complex patterns. Thread consumption averages 200-800 meters per 100 square centimeters depending on design complexity.

Printed fabric production utilizes surface application techniques maintaining original fabric hand and drape characteristics. Ink penetration extends 0.2-2 millimeters into fabric structure, with penetration depth varying based on fabric porosity and ink viscosity specifications.

Durability performance metrics:

Laboratory washing tests demonstrate embroidered elements withstand 500+ wash cycles with minimal degradation when properly executed. Thread selection significantly impacts longevity, with polyester threads showing 40% greater retention compared to rayon alternatives after extended laundering.

Printed designs exhibit variable durability depending on ink chemistry and application methods. Sublimation printing achieves superior wash fastness through molecular bonding, while surface-applied inks may show 15-25% color loss after 100 wash cycles under standard testing conditions.

Tactile characteristics analysis:

Embroidered surfaces create three-dimensional textures with elevation differences measuring 1-5 millimeters above base fabric. This dimensional quality affects drape coefficients, typically reducing fabric flexibility by 20-35% in embroidered areas.

Printed fabrics maintain base textile characteristics with minimal tactile modification. High-quality printing processes add negligible thickness while preserving original fabric hand, breathability, and stretch properties.

Cost analysis factors:

Embroidery production requires specialized equipment, skilled operators, and extended processing times. Average production costs range from ₹664 – ₹2,075 per garment depending on stitch count and design complexity. Setup costs for embroidery designs typically range from ₹4,150 – ₹16,600 per pattern.

Printing processes offer economies of scale with setup costs ranging from ₹2,075 – ₹8,300 per design but variable per-unit costs based on quantity. Digital printing eliminates minimum order requirements while screen printing becomes cost-effective for orders exceeding 100 units.

When to Choose Embroidery Over Prints

Choose embroidery if:

- Professional applications requiring longevity: Corporate uniforms, healthcare garments, and hospitality industry clothing benefit from embroidery's superior wash resistance. Testing data indicates embroidered logos maintain 95% visual integrity after 200 commercial laundry cycles.

- Premium brand positioning requirements: Luxury markets associate embroidery with craftsmanship and quality. Consumer perception studies show 73% premium price acceptance for embroidered versus printed equivalent products.

- Small quantity customization needs: Embroidery equipment accommodates single-piece production efficiently. Setup costs remain consistent regardless of quantity, making individual customization economically viable.

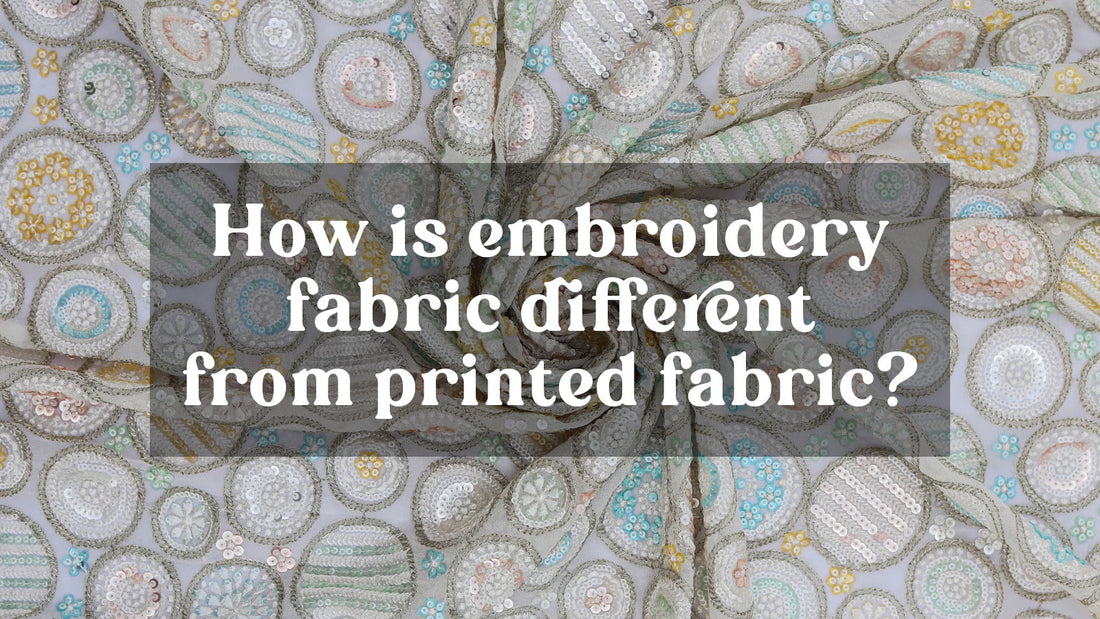

- Textural enhancement objectives: Three-dimensional design requirements necessitate embroidery techniques. Sequin embroidery fabric applications create light-reflective surfaces impossible through printing methods.

- Specialty fabric compatibility: Embroidery works effectively on varied textures including terry cloth, fleece, and technical fabrics where printing adhesion may prove problematic.

Choose printed fabric if:

- Photographic reproduction requirements: Complex imagery, gradients, and photorealistic designs require printing capabilities. Embroidery cannot replicate fine detail below 1-2 millimeter resolution.

- Large-scale production volumes: Quantities exceeding 500 units typically favor printing for cost efficiency. Production speeds of 200+ pieces per hour make printing economically advantageous for volume orders.

- Lightweight fabric applications: Delicate fabrics including silk, chiffon, and lightweight synthetics may not support embroidery tension requirements. Printing maintains fabric integrity without structural modification.

- Wide color palette needs: Printing achieves unlimited color combinations through process mixing. Embroidery thread selection limits color options to available thread inventory, typically 200-400 standard colors.

- Rapid turnaround requirements: Digital printing enables same-day production capabilities. Embroidery typically requires 3-7 days minimum for pattern programming and production completion.

Fabonique technical analysis demonstrates that fabric selection significantly impacts final product performance, with embroidery and printing each offering distinct advantages based on application requirements.

Conclusion

Embroidery and printed fabrics differ in more than just looks. Embroidery is more durable and textured, ideal for premium designs but takes more time and cost. Printing is faster, flexible, and cost-effective for larger batches. The best choice depends on your design, budget, and use. Fabonique suggests choosing based on durability, design needs, and timelines. Visit their online resource center for expert fabric guides and tips.

Shop from Fabonique today! Visit our Instagram profile and Contact us for more details.